Have you ever wondered how gasoline and diesel are made from petroleum? In fact, petroleum is not only a fuel source for transportation but also a raw material for producing a wide range of other important products in life and industry.

In this article, AMN will explore the petroleum processing process and learn about the diverse products created from petroleum, giving you a clearer and more comprehensive understanding of this special resource.

1. Why process petroleum?

Petroleum (crude oil) is a complex mixture of many hydrocarbons, mainly belonging to the alkane series. In its natural state, petroleum cannot be used directly for most purposes in life and production due to its mixed composition, unstable properties, and low efficiency.

Since ancient times, humans have known how to extract petroleum from open-pit mines and used it mainly as fuel for lighting or to treat certain skin diseases. However, the practical value of petroleum was very limited at that time.

It was only with the development of science and technology, especially the advent of fractional distillation, that petroleum was processed into various products such as gasoline, kerosene, diesel, lubricating oil, asphalt, etc. Today, modern refineries continue to refine crude oil using many advanced technologies, creating products with high economic value and meeting the diverse needs of people.

Therefore, petroleum processing is a necessary process, helping to separate, transform, and enhance the value of crude oil, while playing a crucial role in the development of the economy and modern life.

Petroleum is processed at modern refineries

2. Petroleum Processing Methods

Petroleum is a very complex mixture containing hydrocarbons, natural gas, petroleum gas, and many other impurities such as CO2, H2, N2, H2S… Therefore, to be usable, these substances must be separated through distillation to obtain products with different boiling points. The products obtained after distillation are further purified and refined before becoming widely used consumer products such as gasoline, diesel fuel, kerosene, lubricating oil…

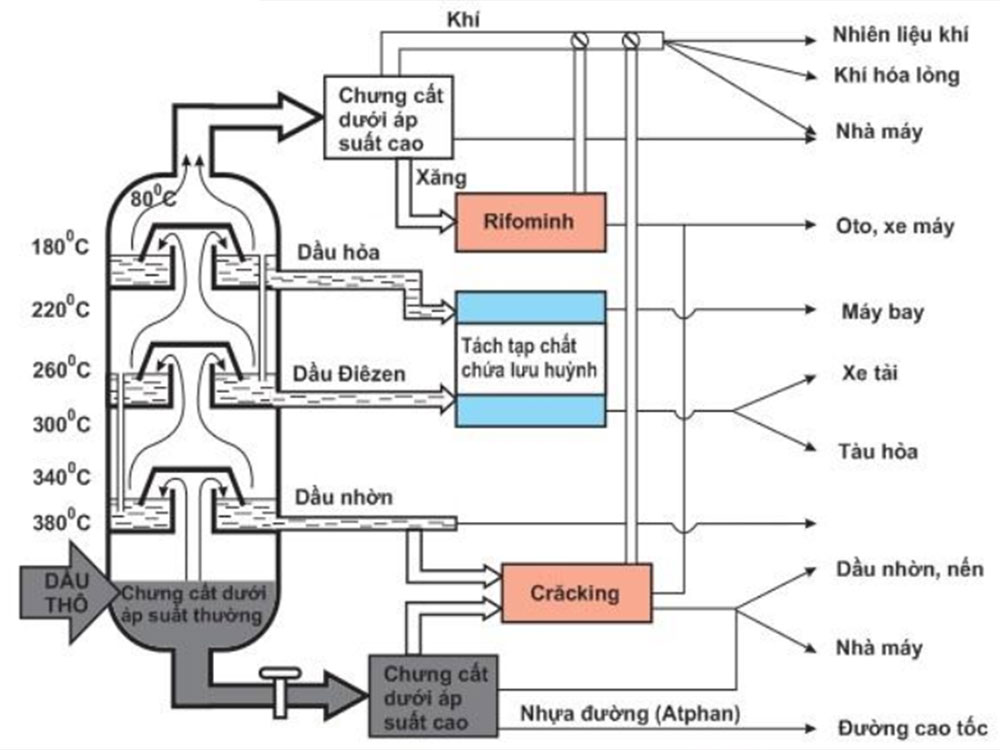

In the fractional distillation process, crude oil is boiled under atmospheric pressure and the temperature is gradually increased to obtain different products. The boiling point range of the products obtained varies depending on the specific stage as follows:

At 40 - 70 °C: ether gasoline is obtained (used as a solvent).

At 60 - 100 °C: light gasoline is obtained (fuel for automobiles).

At 100 - 150 °C: heavy gasoline is obtained (fuel for automobiles).

At 120 - 150 °C: light kerosene is obtained (fuel and solvent).

At 150 - 300 °C: kerosene is obtained (fuel).

At 250 - 350 °C: diesel oil is obtained (fuel for diesel engines or as heating oil).

Above 300 °C: lubricating oil is obtained (used for... (engine lubricant)

Other products such as asphalt, paraffin wax…

Diagram of petroleum fractional distillation

In the first distillation, the amount of gasoline obtained is very low. Therefore, to increase the amount of gasoline obtained, cracking (breaking down heavy hydrocarbon molecules) is used to process low-value heavy products into gasoline and higher-value products. On average, each barrel of crude oil after processing will yield:

8% petroleum gas, mainly composed of light hydrocarbons such as propane, butane…

49% gasoline.

32% aviation fuel, diesel, kerosene, and heating oil.

11% converted into heavy oils, asphalt, and other products.

Besides fractional distillation of crude oil at atmospheric pressure, there are several other methods for processing oil. One example is pyrolysis, which breaks down hydrocarbons to separate petroleum into different fractions under low pressure and temperatures above 650°C

3. Petroleum Products

Petroleum refining and processing is a complex process requiring high technical and technological expertise. After undergoing various refining stages, hundreds of different products can be obtained to serve daily life and production.

Of these, approximately 88% of crude oil is used to produce fuel, while 12% is used in the petrochemical industry to create important chemical raw materials and products.

3.1. Products Obtained During the Refining Process

Some of the main products obtained from the refining process include:

Petroleum gas (petroleum gas): A mixture of gases including methane, ethane, propane, and butane. Petroleum gas is commonly used as fuel for cooking, heating in homes and some industries.

Gasoline: A mixture of alkanes containing 5 to 12 carbon atoms, used as fuel for vehicles such as motorcycles and cars.

Kerosene: A mixture of alkanes containing approximately 10 to 18 carbon atoms, used as fuel for jet engines and aircraft.

Diesel: A mixture of hydrocarbons containing 12 or more carbon atoms, used for diesel engines in cars, ships, trains, and industrial machinery.

Lubricating oil: Consists of alkanes, cycloalkanes, and aromatic compounds with 20 to 50 carbon atoms, used for lubrication, friction reduction, and protection of engines and machinery.

Heavy oil: A liquid containing 20 to 70 carbon atoms, commonly used as fuel in industry and as a feedstock for further processing.

Gasoline is used as fuel for vehicles

3.2. Products Obtained from the Petrochemical Industry

Besides fuel products obtained during oil refining, petroleum is also an important raw material for the petrochemical industry. Through chemical reactions and modern technology, petroleum is transformed into many high-value products, widely used in daily life and production.

Some typical products of the petrochemical industry include:

Chemical fertilizers and pesticides: Petroleum is an important raw material for the production of ammonia – the main component of many fertilizers used in agriculture. In addition, petroleum is used to synthesize many pesticides and plant protection products that are widely used today.

Perfumes and cosmetics: Petroleum derivatives such as petroleum ether, toluene, hexane, and benzene, after refinement, can be used in the production of perfumes, cosmetics, and personal care products.

Vitamins and Pharmaceuticals: Several important vitamins, such as vitamin A, vitamin B6, and vitamin B9, are synthesized from petroleum derivatives. This method is less expensive and more efficient than extraction from natural sources.

Plastics and Polymers: The majority of plastics today are produced from petroleum. While essential in modern life, petroleum is also a major source of environmental pollution if not properly managed and recycled.

In addition, petroleum is used to produce many other products such as aspirin, crayons, chewing gum, wrinkle-resistant fabrics, stockings, solar panels, asphalt, disinfectants, dyes, and many other essential products.

Plastics are one of the derivatives of petroleum

Through this article, AMN has provided you with an overview of products made from petroleum. Hopefully, the information above has helped you understand why petroleum processing is necessary, as well as the important products obtained from petroleum processing in modern life.

Thank you for taking the time to read this article. Don't forget to follow AMN for more useful knowledge and interesting articles in the future!