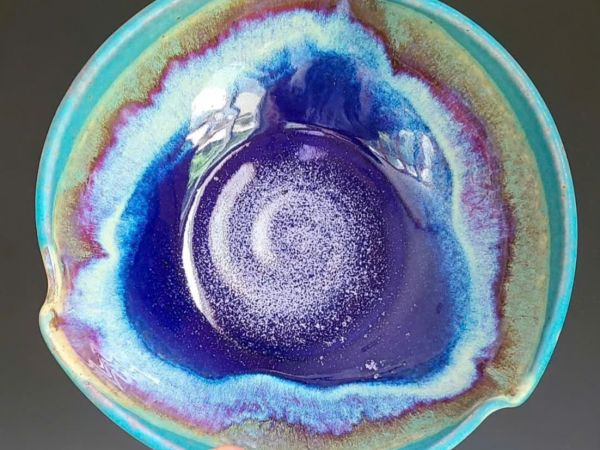

Frit is a glassy object mainly used as glaze in tiles, household ceramics, and coated on metal surfaces. In this article, CMM Vietnam will provide the most basic information about what frit is and where to order frit.

WHAT IS FRIT?

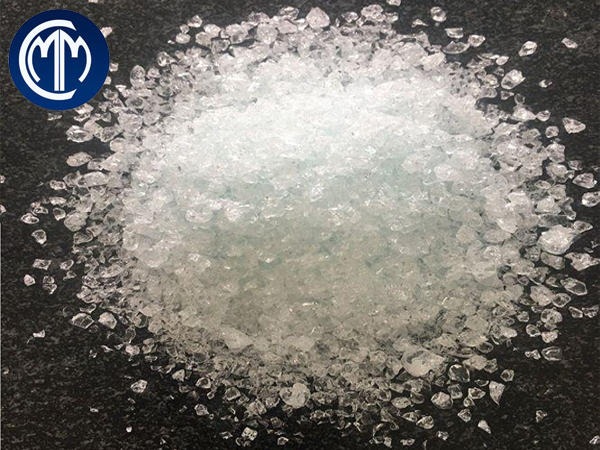

Frit is a type of glassy object created when completely melting the frit mixture (melting in a pot, tank furnace, intermittent rotary furnace at a temperature of 1250-1450°C or higher), then rapidly cooling in water, drying and grinding. Frit glaze is a mixture of frit with a certain amount of auxiliary ingredients or containing mainly frit.

The cause of frit is that many easily melted glaze mixtures contain components that are highly soluble in water (such as soda, boric acid, borax...) or toxic (such as lead oxide). After fritification, the soluble and toxic components are converted to insoluble silicate compounds and their toxicity is reduced.

Frit glazes are easy to settle and have poor adhesion to the wood base when glazing, so frit glazes often contain a certain amount of plastic raw materials such as kaolin, clay, and an appropriate amount of organic glue.

WHERE TO COOK FRITS TO ORDER?

Depending on the customer's desired frit, frit will be cooked in different ovens. For orders with small quantities, it will be cooked in experimental ovens. Orders for industrial production will be cooked in industrial rotary ovens.

Cooking frit with small quantities

Normally, frit will be cooked in small capacity electric or gas ovens.

For the process of cooking frit in electric ovens: the ingredients are loaded into the cup from the beginning. The temperature setting process is set automatically. After the material has been completely melted, it will be discharged into the storage chamber right below.

Advantages of the electric furnace: The process of feeding and discharging the material is not hot; the heating process is automatically set, so it is most convenient for the operator.

The process of taking small samples to check before discharging the material is simple.

Cooking details such as cooking cups, racks, and cooking rods are made of special materials, so they can be reused many times without replacement.

Disadvantages: The initial investment cost is high. Detailed specifications of the electric furnace and price can be seen here.

For the frit cooking process in a small gas furnace: The cooking cup is placed in the furnace from the beginning. The furnace is heated to about 1000°C. Then the cooking cup is taken out and the material is charged. Continue heating until the material is completely melted.

Advantages: Cooking many batches of frit and many single ingredients in the same cooking process.

Disadvantages: Difficult for operators because of high temperatures.

Cooking frit in large quantities

To cook frit in large quantities for industrial applications, the furnace currently used is an intermittent rotary kiln. The ingredients are loaded from the beginning and then heated by LPG until the ingredients are completely melted and discharged into the water tank below. You can watch the video here.

At CMM Vietnam, we provide products and services such as:

+ Cooking frit for hire according to available ingredients

+ Receiving orders to produce frit according to customer requirements in the production of tiles, civil and decorative ceramics, etc.

+ Selling frit and glaze used to produce tiles, civil and decorative ceramics, etc.

Contact us for free consultation and ordering.